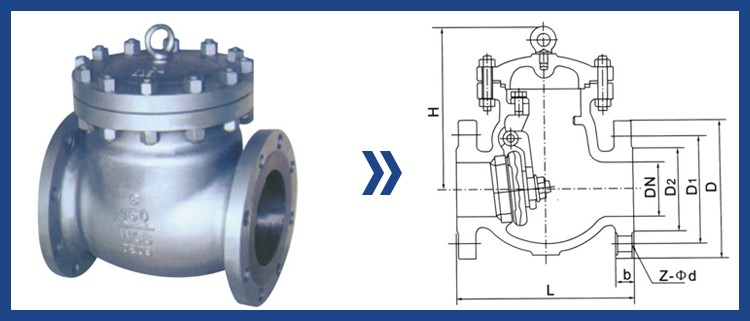

– 316 stainless steel

– 150# flanged ends

– Bolted Cover

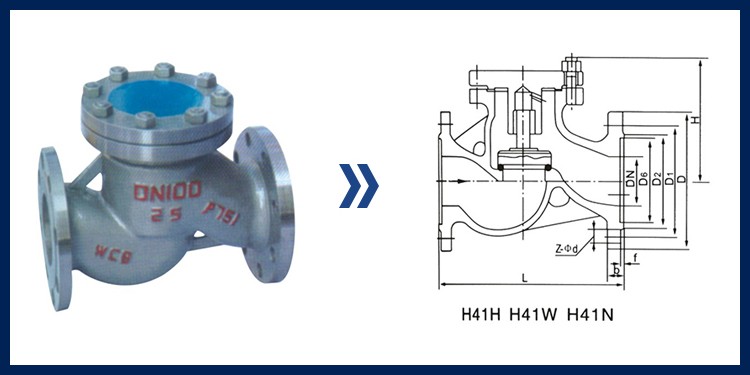

– Swing Type

– Horizontal or Vertical lines

– Welded Seat

– Renewable Seat Rings

– Steel valves ANSI B16.34

– Face to face ANSI B16.10

– End flanges ANSI B16.5

– Buttweld ends ANSI B16.25

– Inspection and test API 598

COVNA company main produce: Vertical Check Valve

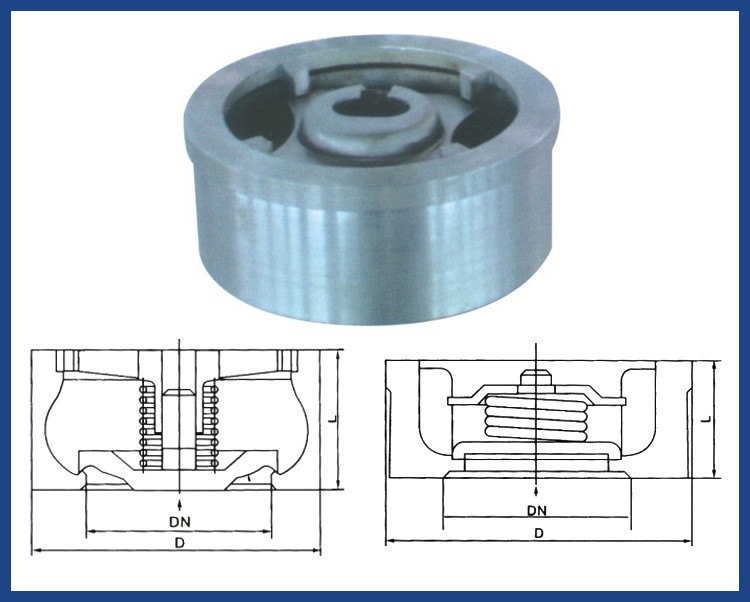

Check valves, also known as one-way check valves or check valves, are designed to prevent backflow of media in the line. The opening and closing parts are opened or closed by the medium flow and force to prevent the medium from flowing backwards. On pipes used for one-way flow of media, only the media is allowed to flow in one direction to avoid accidents. When the inlet side pressure is lower than the outlet side, the flap automatically closes the passage under the action of fluid pressure and its own weight.

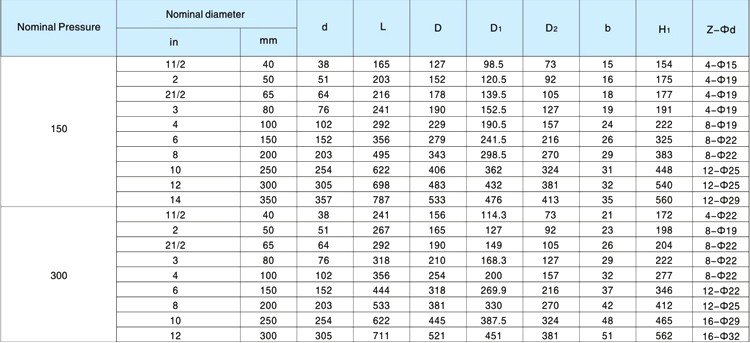

Stainless Steel Flange Check Valve

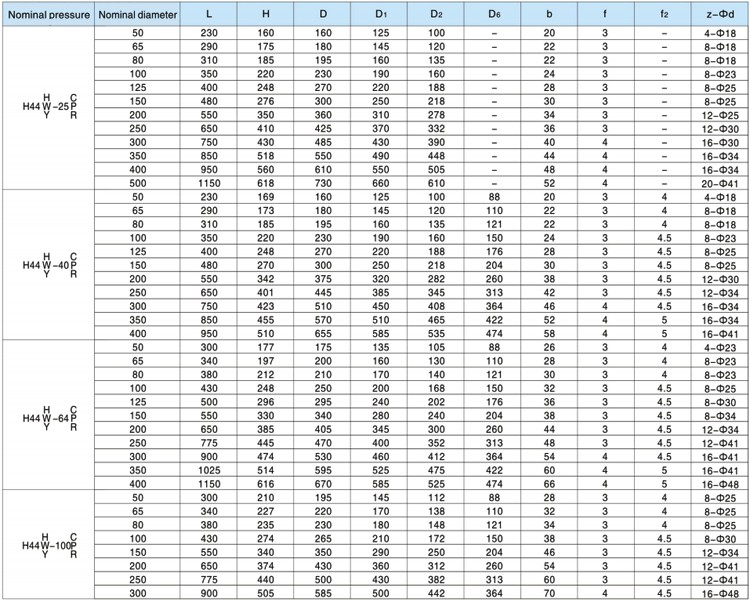

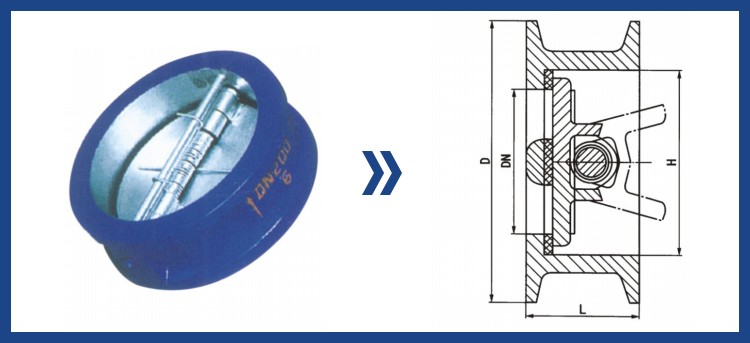

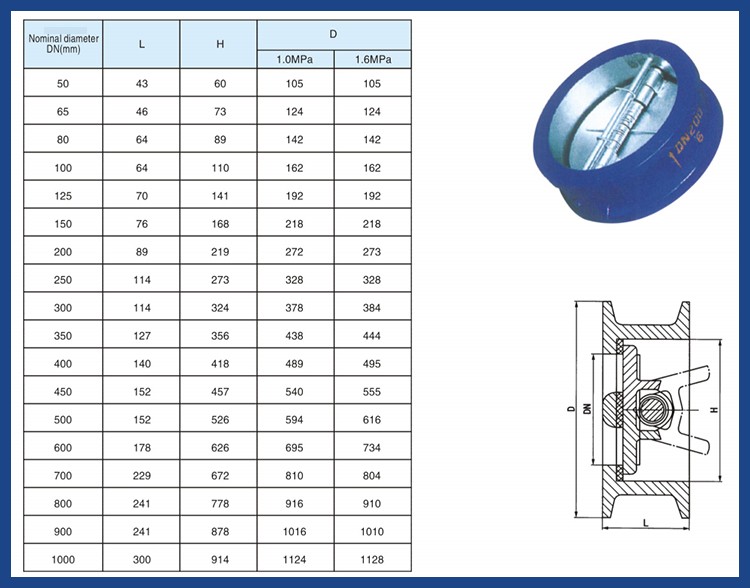

Double Flap Check Valve

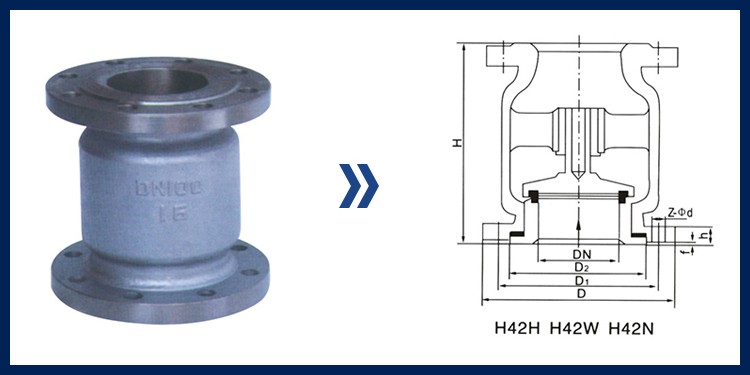

Vertical Check Valve

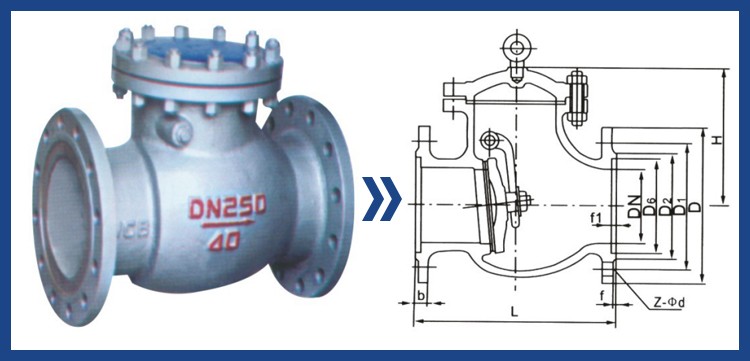

Swing Check Valve

| Specification | |||||

|---|---|---|---|---|---|

| Nominal Pressure | 2.5 | 4.0 | 6.4 | 10.0 | MPa |

| Shell Test | 3.75 | 6.0 | 9.6 | 15.0 | |

| High Pressure Sealing Test | 2.75 | 4.0 | 7.04 | 11.0 | |

| Low Pressure Sealing Test | 0.6 | ||||

| Applicable Medium | C | P | R | N | |

| Water, Oil, Steam. | Nitric, Acid. | Acetic Acid | LPG | ||

| Applicable Temperature | ≤425℃ | ≤100℃ | -40~+80℃ | ||

| Specification | |||||

|---|---|---|---|---|---|

| Test Pressure | PN Nominal Pressure | ||||

| 2.5 | 2.5 | 6.4 | 10 | ||

| Shell Test | 3.75 | 6.0 | 9.6 | 15 | |

| Seal Test(Liquid) | 2.75 | 4.4 | 7.0 | 11 | |

| Seal Test(Gas) | 0.6 | ||||

| Applicable Medium | C | P | R | ||

| Water, Oil, Steam. | Nitric Acid | Acetic Acid | |||

| Applicable Temperature | ≤425℃ | ≤200℃ | ≤200℃ | ||

This kind of check valve is among the products that introduced the advanced foreign technologies. This product adopts the abrasion proof alloy of good quality as the main sealing material and reduces the possibility that the pipe medium will check in low-pressure conditions. Popular among users, the product is widely used in industries of electric power, petroleum, chemical and refining.

| Specification | |||||

|---|---|---|---|---|---|

| Nominal Pressure | 1.0 | 1.6 | 2.5 | 4.0 | |

| Strength Test (Water) | 1.5 | 2.4 | 2.75 | 6.0 | |

| Hight Seal Test (Water) | 1.1 | 17.8 | 38.5 | 44 | |

| Type | H71HWY-10.16.25.40CPR | H71 HWY-10.16.25.40CPR | H71HWY-10.16.25.40CPR | ||

| Material Code | C | P | R | ||

| Applicable Medium | Water, Steam, Air, Oil. | Nitric Acid | Aceticacid | ||

| Applicable Temperature | ≤425℃ | ≤200℃ | ≤200℃ | ||

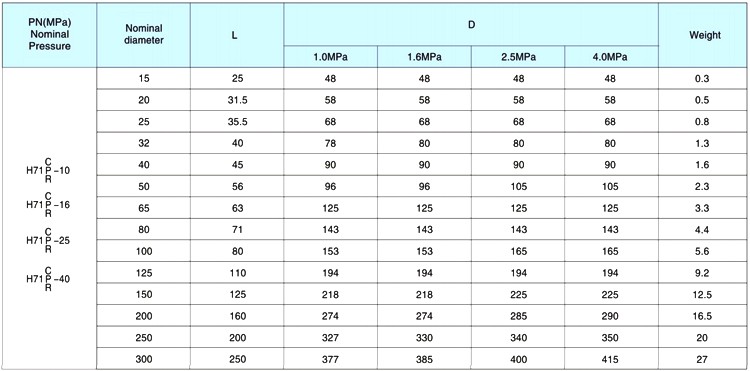

1. Design And Manufacture Comply With BS 1868, JIS B2071

2. Face to Face Dimension Comply

ANSl 150-2500Lb, ANSL B16.10

JIS10/20K, JIS B2001

3. Connection Flange

ANSI 150-2500Lb, ANSL B16.5

JIS10/20K, JIS B2212, B2214

4. Test and inspection ace to API 598

WCB, WC6, WC9, CF8, CF8M, CF3, CF3M

| Main Technique Number | |||||

|---|---|---|---|---|---|

| Type | Nominal PN(MPa) | Test Stre Ngth Pressure (MPa) | Test Seal Pressure (MPa) | Applicable Temperature (℃) | Applicable Media |

| H76X-10 H77X-10 | 1.0 | 1.5 | 1.1 | ≤80 | Clean-water Slops Sea |

| H76X-16 H77X-16 | 1.6 | 2.4 | 1.76 | ||

| Material For Main Parts | |||||

|---|---|---|---|---|---|

| Name Of Part | Body | Disc | Stem | Spring | Seat |

| Material | Bowl-shaped, Steel, Stainless Steel. | Bowl-shaped, Steel, Stainless Steel. | Stainless, Steel. | Stainless, Steel. | NBR, Stanless, Steel |

This valve is a safety device mounted in the pipeline or pump outlet to prevent the pump from inversed running due to the differential water hammer’s shock in the pipeline when the pump stops and features a brand-new structure, small volume, light weight,small fluid resisteance, reliable seal, stable open-close, long duration, better energy-saving effect.

Suitable for the pipeline related to water supply and drainage, fire-fighting, warming etc. Systems or the pump outlet to prevent both pump and pipeline from being damaged due to the water hammer produced when the medium flows back and form the silencing effect.

| Main Technique Number | |||||

|---|---|---|---|---|---|

| Nominal Pressure Pn (mm) | 1.0 | 1.6 | |||

| Test Pressure (Mpa) | Shell Strength | 1.5 | 2.4 | ||

| Sealing Performance | 1.1 | 1.76 | |||

| Working Temperature(℃) | ≤80 | ||||

| Applicable Medium | Clean-water, Sea. | ||||

| Slow-close Time(S) | 0~60 | ||||

| Material For Main Partes | |||||

|---|---|---|---|---|---|

| Name Of Part | Body | Disc | Stem, Oil Cylinder, Oil Cork | Spring | Seat |

| Material | CI, Bowl-shaped, Steel | Bowl-Shaped, Steel, Stainless Stee | Stainless Steel | Stainless Steel | NBR |

COVNA company main produce: Vertical Check Valve